-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

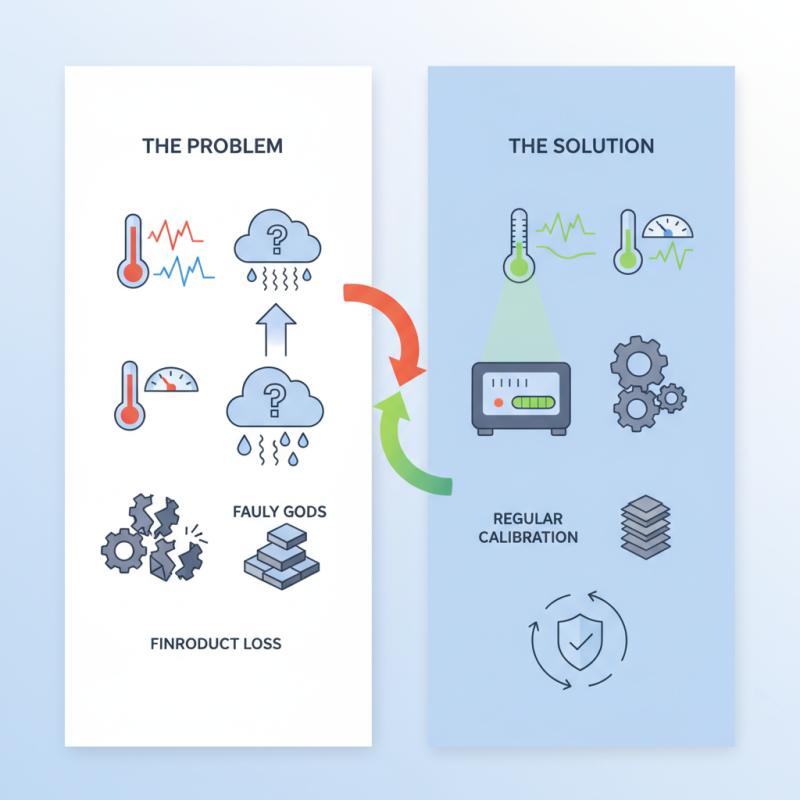

In industries where precision is key, Temperature And Humidity Calibration Equipment becomes indispensable. Incorrect measurements can lead to faulty products and financial loss. As noted by Dr. Emily Foster, a leading expert in calibration technology, "Accurate calibration is the backbone of quality control." Her insights emphasize the crucial role this equipment plays in ensuring reliability.

Many organizations overlook the importance of consistent calibration practices. They often believe that once calibrated, their equipment will remain accurate indefinitely. However, environmental factors can cause shifts in measurements over time. For instance, temperature fluctuations can affect readings, leading to errors in manufacturing processes.

Regular use of Temperature And Humidity Calibration Equipment can mitigate these risks. Investing in quality calibration tools may seem costly initially, but the long-term benefits outweigh the drawbacks. Unchecked inaccuracies can have devastating consequences. Reflection on current calibration practices can often reveal gaps that need addressing for improved outcomes.

Accurate temperature and humidity measurements are crucial in various industries. Calibration is essential to ensure these measurements are reliable. According to a report by the National Institute of Standards and Technology (NIST), a mere 1°C deviation can lead to significant errors in experimental results. This shows how precision matters in fields like pharmaceuticals or food safety.

Humidity impacts many processes. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) states that inaccurate humidity readings can affect product quality. For example, in the textile industry, wrong humidity levels can lead to fabric defects. A study indicated that fluctuations of just 5% in relative humidity can change the moisture content in materials by 20%.

Calibration often reveals inconsistencies. Many laboratories find their measuring equipment out of compliance during routine checks. This highlights the need for regular calibration. Additionally, environmental factors can change equipment performance over time. Relying on outdated measurements might lead to costly errors that could have been avoided with better practices. Thus, maintaining rigorous calibration protocols is not just a recommendation; it's a necessity.

Calibration equipment plays a crucial role in environmental monitoring. Accurate measurement is vital in sectors like agriculture, pharmaceuticals, and climate studies. According to a report by the National Institute of Standards and Technology, a mere 1% error in temperature readings can lead to significant discrepancies in research outcomes. Precision is not just a bonus; it's essential for reliable data collection.

Humidity levels also impact results. For instance, a study published in the Journal of Environmental Monitoring states that fluctuations of just 5% in humidity can skew results in controlled experiments. Without proper calibration, these errors could compromise entire research projects. It's alarming how often calibration is overlooked. Many organizations underestimate the ongoing need for accurate instruments.

Failure to recalibrate can lead to false confidence in data. In environmental monitoring, even small inaccuracies can lead to misleading conclusions. This vulnerability emphasizes the necessity of consistent calibration. Researchers must prioritize this aspect to maintain integrity in their work. Calibration equipment is more than a tool; it's a lifeline for credible environmental assessment.

| Parameter | Standard Range | Typical Calibration Frequency | Impact of Inaccuracy |

|---|---|---|---|

| Temperature | -40°C to 100°C | Annually | Compromised data integrity and equipment performance |

| Humidity | 0% to 100% RH | Bi-annually | Incorrect moisture readings affecting product quality |

| Dew Point | -30°C to 60°C | Once a year | Risk of condensation and mould growth |

| Air Pressure | 950 hPa to 1050 hPa | Every two years | Effects on closed environments and calibration of other instruments |

Temperature and humidity calibration systems comprise several key components. One important element is a precise sensor. These sensors measure environmental conditions accurately. They help ensure that readings are reliable and consistent. Calibration often requires a temperature and humidity chamber. This chamber simulates various conditions for testing. It plays a crucial role in maintaining accuracy during calibration.

Controllers are vital too. They manage the temperature and humidity settings with precision. A good controller can adjust the conditions quickly. Another critical component is the reference standard. This device provides a benchmark for accuracy. It helps in assessing the performance of sensors. Regular checks with a reference standard can expose any deviations.

However, calibration systems must be maintained properly. Even minor faults can lead to inaccurate readings. Dust buildup can affect sensor performance. Regular cleaning and maintenance are essential. Users often overlook these details, but they are crucial. Calibration is not a one-time process. It requires constant attention and periodic verification. This ensures that the equipment remains reliable over time.

Calibration of temperature and humidity instruments plays a crucial role in ensuring accuracy. According to a report by the International Organization for Standardization, inaccuracies can lead to data discrepancies of up to 25%. This not only affects measurement reliability but can also lead to significant financial losses in industries like pharmaceuticals and food production.

Inaccurate instruments can compromise product quality. For instance, improper humidity levels can spoil sensitive materials. A survey by the American Society for Quality found that 15% of manufacturers experienced loss due to uncalibrated equipment. This emphasizes the need for routine calibration checks to improve instrument performance.

**Tips:** Regularly schedule calibration sessions. Do not wait until an instrument malfunction is evident. Track calibration history for transparency. Consider environmental factors that could influence readings. Remember, neglected calibrations can lead to repeated mistakes and unreliable data.

This bar chart represents the importance of calibration in maintaining the accuracy of temperature and humidity instruments. The data reflects the percentage of accuracy changes over a 12-month period in different calibration scenarios.

Temperature and humidity calibration equipment plays a critical role in maintaining accuracy in various industries. Regular maintenance and proper handling of calibration tools are vital for ensuring their reliability. When equipment is not maintained, errors can occur, leading to poor decision-making based on inaccurate data.

One effective practice is to schedule frequent inspections. An internal study found that equipment checked every three months showed a 30% increase in accuracy compared to those assessed annually. Calibration should be performed in controlled environments. Additionally, avoid exposing equipment to extreme conditions to preserve effectiveness.

Tip: Always keep calibration records updated. Documentation helps track performance over time.

Using proper storage can extend the lifespan of instruments. Storing equipment in dust-free environments prevents contamination. Regularly cleaning sensors and components reduces the risk of errors. If you notice discrepancies in readings, reassess both the equipment and the environment.

Tip: Make cleaning a routine task. A clean instrument is a reliable instrument.

Calibration equipment should be treated with care. Over time, careless handling can degrade performance. Investing time in training staff to handle these tools properly promotes longevity. Creating a culture of precision within your organization ultimately results in enhanced accuracy.