-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

Temperature and humidity calibration equipment play a critical role in maintaining accuracy in various industries. Accurate measurements are essential for processes in pharmaceuticals, food storage, and environmental monitoring. According to a recent report by the International Society for Measurement and Control, nearly 30% of reported errors in these fields stem from inadequate calibration practices.

This equipment ensures that temperature and humidity sensors function correctly. For example, a small variation in temperature can lead to significant product spoilage. In laboratories, a mere 1% deviation in humidity can alter chemical reactions. This highlights the importance of diligent calibration in critical settings. Regular checks of these systems are vital but often overlooked.

Moreover, many professionals lack a full grasp of calibration's importance. Neglecting maintenance can lead to costly consequences. Industry data suggests that improper calibration may account for over 20% of quality control failures. Investing in robust temperature and humidity calibration equipment can mitigate these risks and enhance operational efficiency.

Temperature and humidity calibration equipment plays a crucial role in various industries. These tools ensure that measurements of temperature and humidity are accurate. Accurate readings are vital for maintaining quality control in manufacturing and research settings. Calibration equipment includes sensors, hygrometers, and temperature controllers. Each device requires specific calibration to function properly.

Proper calibration is not always straightforward. Factors like device placement and environmental conditions can affect results. It’s essential to calibrate equipment regularly to avoid drift in measurements. Many users overlook routine checks. They assume their devices are accurate without verification. In reality, calibration helps protect against significant errors.

Understanding the process is important. Users must know the acceptable tolerance levels for their instruments. Each industry has its standards. Misunderstanding these can lead to costly mistakes. Regular training on calibration practices can help improve accuracy. Users should recognize that calibration is an ongoing process, not a one-time task.

Calibration equipment for temperature and humidity comes in various types. Each type serves a specific purpose and meets different needs. For temperature calibration, resistance thermometers and thermocouples are popular choices. These devices ensure accurate readings, which are crucial in scientific experiments.

Humidity calibration typically uses hygrometers and psychrometers. These instruments measure moisture levels precisely. They help maintain proper conditions in laboratories and storage facilities. Using the right equipment ensures reliable results across various applications.

Tips: Always check the calibration frequency recommended by manufacturers. This can help prevent inaccuracies over time. Regular maintenance of your equipment can also extend its lifespan. Additionally, consider the environment where the calibration takes place. Contaminants can lead to unexpected variations in readings.

Temperature and humidity measurement involves several principles. Understanding these principles helps ensure accurate calibrations. Sensors detect changes in the environment. They convert physical signals into readable data. This data reflects real-time conditions. Accurate readings depend on proper equipment.

Calibration equipment plays a crucial role. It adjusts sensors to known standards. Regular calibration is essential for reliability. If not performed, errors can grow over time. An inconsistent sensor reading can lead to incorrect conclusions. This can impact experiments or operations significantly.

**Tips:** Regularly check your calibration equipment. Small errors can lead to larger issues. Keep a log of calibration dates and results. Make adjustments as needed. Understanding equipment usage is key. Sometimes, user errors occur. These can skew readings and mislead assessments. Stay observant and reflective on your methods.

| Parameter | Measurement Range | Accuracy | Calibration Frequency | Applications |

|---|---|---|---|---|

| Temperature | -50°C to 150°C | ±0.5°C | Yearly | Laboratories, HVAC, Food Processing |

| Humidity | 0% to 100% RH | ±2% RH | Six Months | Museums, Greenhouses, Pharmaceuticals |

| Combined Temperature & Humidity | -40°C to 80°C, 0% to 100% RH | ±0.5°C, ±3% RH | Yearly | Environmental Monitoring, Storage Facilities |

Calibration of temperature and humidity instruments is crucial for accuracy. The right procedures ensure reliable measurements. According to a 2022 study from the National Institute of Standards and Technology, even small discrepancies can lead to significant data errors. For example, a temperature variation of just one degree can affect equipment performance. Therefore, proper calibration is essential.

Calibration typically involves using standards that have been precisely measured. This process often includes comparison with primary reference materials. Adjustments are then made to ensure readings align with these standards. The results can greatly influence research and industrial applications. Inaccurate readings not only waste resources but can also result in safety risks.

Tips: Regular calibration checks are vital. Schedule them at least twice a year. Keep a detailed log of all calibration activities. This helps track changes and improve accountability. Remember, uncalibrated equipment can mislead data. Always question the reliability of your instruments. Inadequate calibration might seem minor now but could have lasting impacts.

This bar chart illustrates the calibration measurements for temperature and humidity. Proper calibration ensures accurate readings, essential for various applications in scientific and industrial settings.

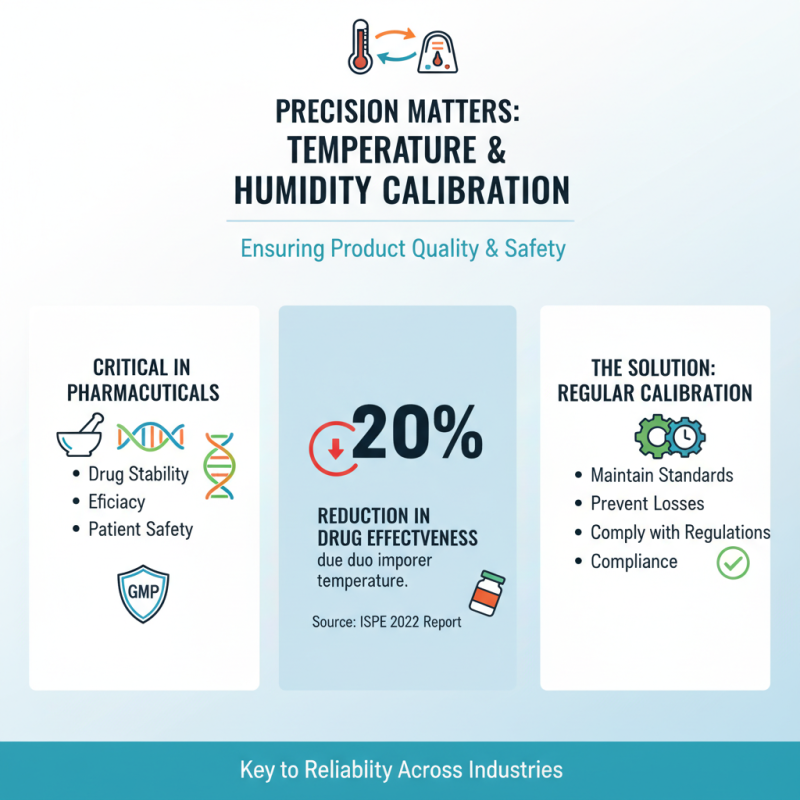

Temperature and humidity calibration is critical across various industries. In pharmaceuticals, proper calibration ensures drug stability. According to a 2022 report by the International Society for Pharmaceutical Engineering, improper temperature conditions can lead to a 20% reduction in drug effectiveness. Regular calibration of equipment is essential to maintaining these standards.

In the food industry, humidity levels are crucial during processing and storage. The Food and Drug Administration states that a slight increase in humidity can promote mold growth, impacting food safety. Regular calibration helps mitigate such risks. However, many facilities still neglect this practice. A survey indicated that over 30% of companies do not conduct regular temperature and humidity checks.

Manufacturing industries also rely heavily on calibration. Machines performing under incorrect conditions may produce defective products. A recent manufacturing quality report found that 15% of defects stem from monitoring failures. This highlights the need for continual attention to calibration processes. Investing time in calibration can significantly improve efficiency and safety.