-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

In the realm of modern energy management, the effective utilization of Heat Flux Sensors has become increasingly vital for optimizing energy efficiency and reducing consumption. These sensors, which measure the rate of heat transfer per unit area, provide invaluable data that can enhance the performance of HVAC systems, improve building envelope integrity, and facilitate better thermal management in industrial processes. As businesses and homeowners alike seek sustainable solutions to meet escalating energy demands, integrating Heat Flux Sensors into energy management strategies presents an opportunity to gather precise thermal insights, enabling informed decision-making and strategic interventions. This article will explore best practices and methodologies for leveraging Heat Flux Sensors, highlighting their role in creating smarter energy systems and advancing overall sustainability goals.

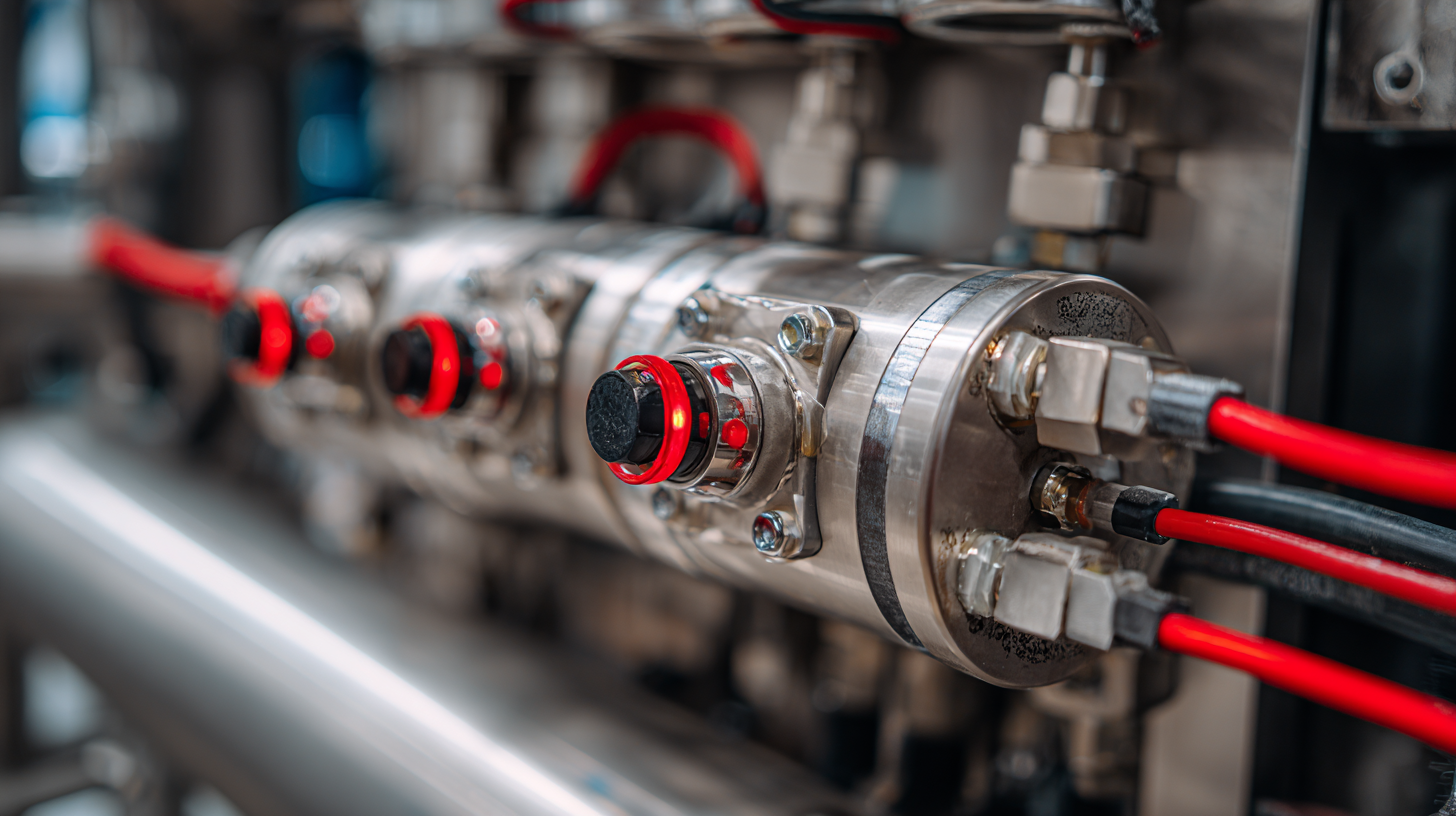

Heat flux sensors play a pivotal role in modern energy management, particularly in monitoring and optimizing energy systems. Understanding the types and applications of these sensors is crucial for enhancing performance in various sectors, including renewable energy, HVAC, and industrial processes. For instance, sensors can measure thermal conductivity and heat transfer efficiency, allowing for real-time adjustments that significantly reduce temperature gradients in conductors and busbars of transmission systems. This optimization not only improves energy efficiency but also extends the lifespan of the components involved.

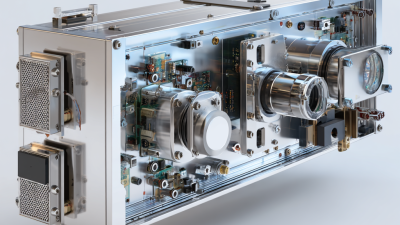

In the realm of renewable energy, heat flux sensors are essential for managing the performance of photovoltaic thermal systems. By accurately measuring the heat absorbed by PV panels, these sensors help to balance the conversion of solar radiation into electrical energy with the thermal energy that is otherwise dissipated. Advanced technologies, such as roll-to-roll printing of thermopiles, are being developed to create more sensitive and effective sensors that can directly convert heat flux into electrical signals. Integrating these innovations into energy management frameworks can lead to substantial advancements in energy savings and overall system efficacy.

Integrating heat flux sensors into existing energy management frameworks presents a significant opportunity to enhance energy efficiency and optimize resource allocation. These sensors provide real-time data on thermal energy transfer, enabling managers to make informed decisions based on precise measurements. By incorporating this technology into current systems, organizations can identify energy losses, improve process efficiency, and ultimately reduce operational costs. The integration process begins with assessing the current energy management framework, ensuring compatibility with the new data streams from heat flux sensors.

Furthermore, establishing a centralized data analysis platform is crucial for maximizing the benefits of heat flux sensors. This platform can synthesize information from various sources, allowing for comprehensive monitoring of energy performance. By leveraging advanced analytics and machine learning algorithms, companies can predict energy consumption patterns, optimize heating and cooling systems, and identify anomalies that may indicate inefficiencies or equipment issues.

As businesses aim for greater sustainability, the seamless integration of heat flux sensors into their energy management strategies will be vital for achieving both economic and environmental goals.

When utilizing heat flux sensors in modern energy management, best practices for data collection and analysis play a critical role in maximizing their effectiveness. First, ensuring proper placement of sensors is essential; locations should be chosen based on the specific heat transfer paths relevant to the energy systems being monitored. This strategic placement helps in capturing accurate heat flux data, which can significantly impact energy efficiency evaluations. Additionally, calibrating sensors before deployment is vital to achieving reliable measurements and minimizing errors in data interpretation.

Once the data is collected, thorough analysis is necessary to extract meaningful insights. Employing advanced data analytics techniques, such as machine learning algorithms, can enhance the comprehension of heat flux patterns and anomalies. Utilizing visualization tools allows for clearer interpretation of data, enabling energy managers to make informed decisions quickly. Regularly reviewing collected data in conjunction with operational performance metrics can lead to improved energy management strategies and optimize the overall efficiency of energy systems.

Heat flux sensors are pivotal in enhancing energy efficiency by enabling real-time monitoring of thermal conditions within various systems. By accurately measuring the flow of heat across materials, these sensors help identify energy losses and optimize processes in manufacturing and building management. For example, integrating heat flux sensors into smart monitoring systems allows for dynamic adjustments in energy usage, ensuring that resources are conserved and operational efficiencies are maximized.

Furthermore, the deployment of these sensors in applications such as metal forming and building envelope management can significantly impact overall energy performance. In metal forming processes, capturing real-time data on heat transfer enables engineers to fine-tune parameters for improved material properties and reduced energy consumption. Similarly, continuous monitoring of building U-values through low-cost heat flux sensor technology enables facility managers to maintain optimal thermal comfort while minimizing energy expenditure.

By leveraging these innovative tools, organizations can drive sustainability initiatives and advance toward a more energy-efficient future.

The implementation of heat flux sensors in energy management has been transformative for various industries, showcasing their effectiveness through several compelling case studies. For instance, the industrial sector has seen a high return on investment (ROI) through the integration of these sensors. A report by the American Society of Mechanical Engineers (ASME) estimates that companies can reduce energy consumption by up to 30% when utilizing heat flux measurements to optimize their thermal processes. This significant reduction not only lowers operational costs but also contributes to sustainability goals.

In the residential sector, smart home technology is revolutionizing energy management. A case study from the U.S. Department of Energy highlights a pilot program where households equipped with heat flux sensors achieved an average energy savings of 15%. By continuously monitoring heat transfer in real-time, homeowners can adjust their heating and cooling systems dynamically, leading to enhanced energy efficiency. The data from these implementations underscore the critical role that accurate heat flux measurement plays in driving effective energy management strategies across various sectors.