-

Home

-

Product Center

-

Application

-

Support

-

JT Cloud

-

About Us

-

Contact Us

Leave Your Message

In recent years, China's advancements in manufacturing have marked a significant shift towards quality and innovation, particularly in the sector of Air Velocity Transmitters. According to a report by MarketsandMarkets, the global air velocity transmitter market is projected to grow from USD 1.1 billion in 2021 to USD 1.5 billion by 2026, reflecting a CAGR of 5.2%. As industries increasingly prioritize precision and reliability in their operational processes, the demand for high-quality air velocity transmitters is skyrocketing. Chinese manufacturers, with their robust investments in research and development, are now at the forefront of this quality revolution, developing products that not only meet but exceed international standards.

This blog will explore how China is leading the world in the production of premium air velocity transmitters, and the significant impact this has on various industries, including HVAC, pharmaceuticals, and environmental monitoring.

The manufacturing of high-quality air velocity transmitters poses several challenges that must be addressed to maintain competitiveness in the global market. As companies strive to enhance measurement accuracy and reliability, it is essential to invest in advanced technologies and skilled personnel. According to a recent report by MarketsandMarkets, the air velocity transmitter market is expected to grow from USD 1.2 billion in 2023 to USD 1.8 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth underscores the need for manufacturers to continuously innovate and improve their quality standards.

One significant challenge is ensuring the durability and precision of sensors under varying environmental conditions. A report from BCC Research highlights that nearly 25% of air velocity transmitters fail to meet industry performance standards due to environmental factors such as humidity and temperature fluctuations. Moreover, adherence to stringent international quality certifications, such as ISO 9001, adds another layer of complexity, requiring manufacturers to implement robust quality control processes. Overall, overcoming these challenges is essential for companies looking to leverage China’s quality revolution and establish a strong position in the premium air velocity transmitter market.

The increasing emphasis on quality standards in the field of air velocity transmitters is transforming their performance and reliability, which is crucial for enhancing indoor air quality across various environments. Recent studies highlight the significant impact of air quality and thermal comfort in settings like large stadiums during events or in public transportation systems. These insights reinforce the importance of advanced air velocity transmitters, as they directly influence airflow management, comfort levels, and overall environmental quality.

Moreover, innovations in air velocity technology can effectively address the challenges associated with maintaining optimal indoor conditions. For example, research on the relationship between air quality and multiple factors underscores the necessity for reliable air velocity measurements that inform ventilation strategies. By improving these standards, air velocity transmitters are not only becoming pivotal in ensuring a healthy indoor atmosphere but also in driving productivity and well-being in educational and public spaces. As China leads this quality revolution, the global community can expect enhanced standards that set the benchmark for air quality management in various sectors.

In the rapidly evolving field of industrial automation, air velocity transmitters play a crucial role in ensuring optimal system performance and energy efficiency. However, common issues in their calibration and maintenance can significantly impact the accuracy of measurements. A recent report by the International Society of Automation highlights that nearly 30% of air velocity transmitters in use today are improperly calibrated, leading to substantial discrepancies in airflow measurements. This is especially critical in sectors like HVAC and manufacturing, where precise airflow control directly affects energy consumption and operational safety.

Furthermore, regular maintenance is essential to mitigate performance issues. Studies indicate that a staggering 40% of air velocity transmitters suffer from wear and tear due to environmental factors such as dust and humidity, which can degrade sensor performance over time. Implementing a systematic maintenance schedule that includes routine checks and recalibrations can enhance the lifespan of these instruments and, in turn, the efficiency of systems at large. Ensuring quality control in calibration and maintenance is not just a best practice; it is a necessity for industries aiming for high standards in operational excellence and sustainability.

| Issue | Description | Frequency of Occurrence | Common Solutions | Maintenance Tips |

|---|---|---|---|---|

| Calibration Drift | Deviation of output signal from original calibration settings. | Frequent | Perform regular calibration checks, adjust settings as necessary. | Ensure stable environment conditions during calibration. |

| Sensor Obstruction | Physical blockage affecting airflow to the sensor. | Moderate | Regularly inspect and clear any obstructions around the sensor. | Implement routine maintenance checks. |

| Power Supply Issues | Fluctuations in power affecting transmitter performance. | Occasional | Use stable power supplies with voltage regulation features. | Monitor power supply continuously for irregularities. |

| Temperature Variability | Temperature changes affecting sensor readings. | Common | Allow sensors to acclimatize before use; use temperature compensation. | Store equipment in stable temperature environments. |

| Software Malfunctions | Issues with the software interface used for calibration and data logging. | Rare | Regular software updates and backups. | Conduct routine checks for software integrity. |

In the landscape of industrial automation, air velocity transmitters are pivotal for ensuring efficiency and accuracy across various applications. However, reliability issues often plague these devices, leading to inconsistent data and operational disruptions. To address these challenges, manufacturers are adopting innovative strategies focused on enhancing the durability and precision of air velocity transmitters.

One key approach involves rigorous testing protocols that mimic real-world conditions, allowing manufacturers to identify potential weaknesses before products reach the market. Additionally, the integration of advanced materials and technology plays a crucial role in improving the reliability of these instruments. For instance, utilizing high-performance sensors and robust casing reduces susceptibility to environmental factors that typically compromise reliability.

Furthermore, ongoing collaboration between researchers and industry professionals facilitates the continuous evolution of design standards. By investing in research and development, companies can develop smarter algorithms that improve data interpretation and sensor calibration. This commitment to quality not only positions China as a leader in air velocity transmission technology but also sets a benchmark for global manufacturing standards, further pushing the envelope on reliability and performance.

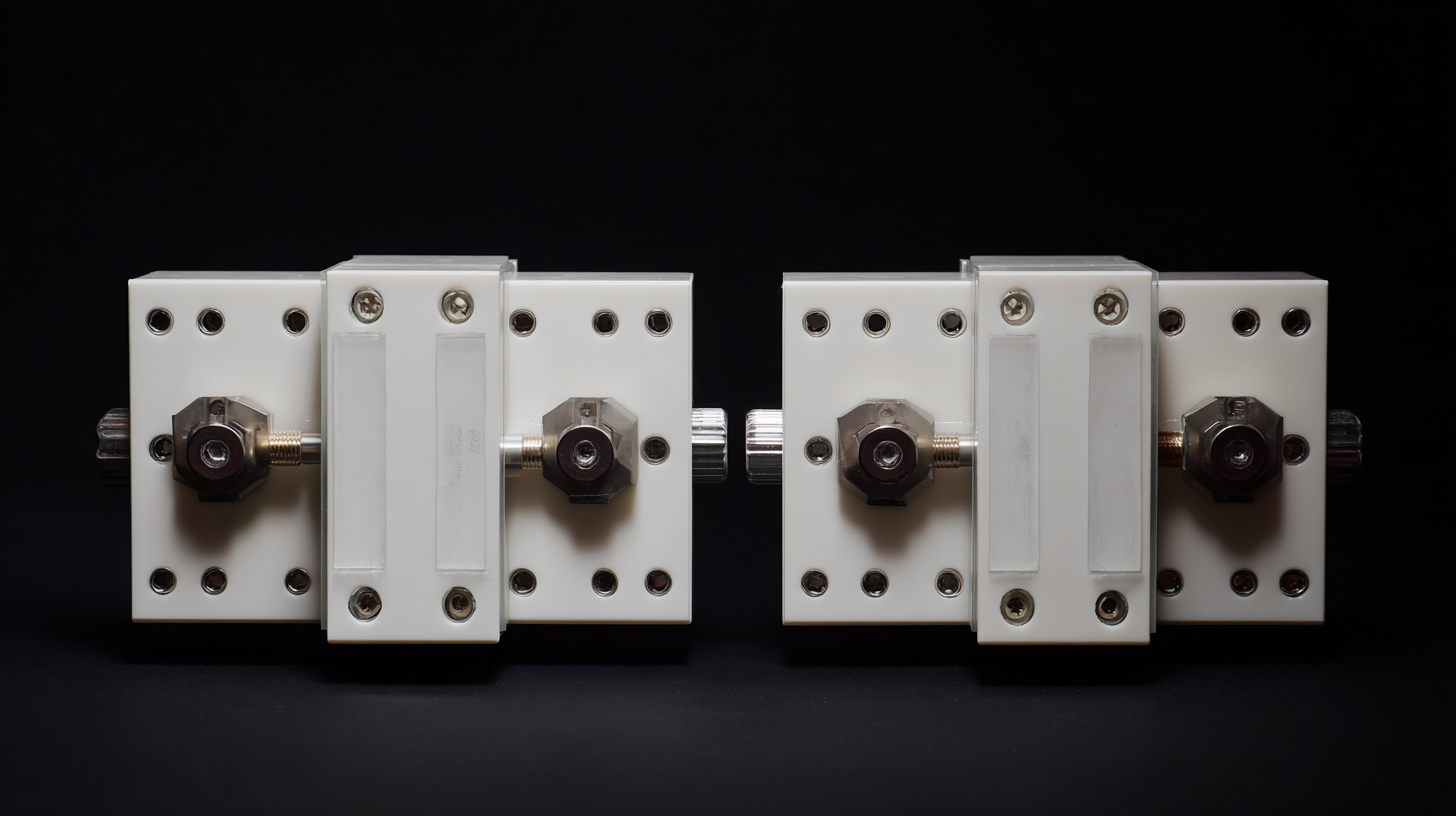

In recent years, China's advancements in technology have set a new benchmark in the production of air velocity transmitters. These devices are essential in various industries for monitoring airflow, ensuring operational efficiency, and maintaining safety. By focusing on innovative solutions, Chinese manufacturers are enhancing both the precision and durability of their products, ultimately leading the global market in high-quality instrumentation.

One of the significant breakthroughs in air velocity transmitter design is the incorporation of advanced materials and smart sensor technology. This not only boosts measurement accuracy but also extends the lifespan of the devices. Enhanced algorithms and calibration techniques further improve reliability in diverse environmental conditions, making these transmitters ideal for use in everything from HVAC systems to industrial manufacturing. As the push for sustainable practices increases, these innovations are paving the way for more energy-efficient systems that meet modern demands.

Moreover, the emphasis on quality control in production processes ensures that these air velocity transmitters outperform the competition. Rigorous testing and adherence to international standards guarantee that each unit is capable of enduring harsh conditions while providing real-time, precise data. As countries around the world seek to elevate their technological infrastructures, China's commitment to excellence in air velocity transmitter manufacturing positions it as a leader in the global market.